Maximize Efficiency & Technology

Evaluating significant investments in new technology can seem overwhelming. Hytech Partners enables you to make these decisions with confidence, delivering order and efficiency to your plant floor.

Looking for help? Get in touch with us

State-of-the-art injection molding and process technology.

Innovation and technological advancement for maximum customer benefit are the fundamental principles of our injection molding technology.

This modern and comprehensive range of machinery, in a modular and energy efficient design, meets the actual and future requirements of the market.

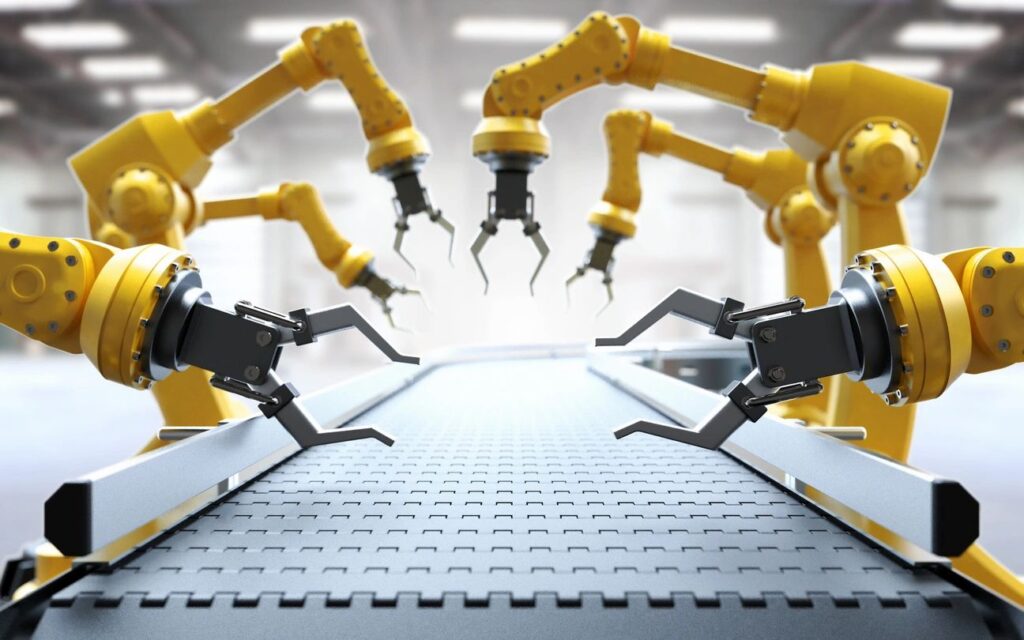

An entire range of robots for the flexible automation of injection molding machines – from small models, up to machines with very large clamping forces.

Our CNC robots and IML systems have reached a leading market position through technical innovation, performance, and reliability.

Optimizing production processes and to improving part quality in every single case.

Everything around the injection molding machine: the very best units guarantee absolute process security.

Range of equipment covers all application areas: drying, conveying, blending, temperature controller’s, recycling and extrusion.

We represent the leading manufacturers of auxiliary equipment needed for plastics processing

Humans & Robots Working Together

Streamline your processes and enable your workforce to focus higher level tasks within your operation. Utilize CoBots for tasks that are repetitive and potentially dangerous for the safety of your workforce and efficiency to process

We specialize in developing and implementing advanced technology automation platforms configured to meet your unique, specific strategic goals and objectives. Whether your manufacturing challenges require a custom system or one of our patented product platforms, Hytech Partners will develop a process solution tailored to your unique needs.

High performance, reliable, and energy efficient process water systems and equipment.

- Variable frequency drives

- High efficiency pumping

- Evaporative cooling

- Free cooling (economizer)

- High efficiency chillers

- Capacity vs Load modeling

- Predicted energy savings calculations